INSTALLATION

OUR PRODUCTS

RECOMMENDATIONS FOR THE INSTALLATION OF RIBBED SHEETS

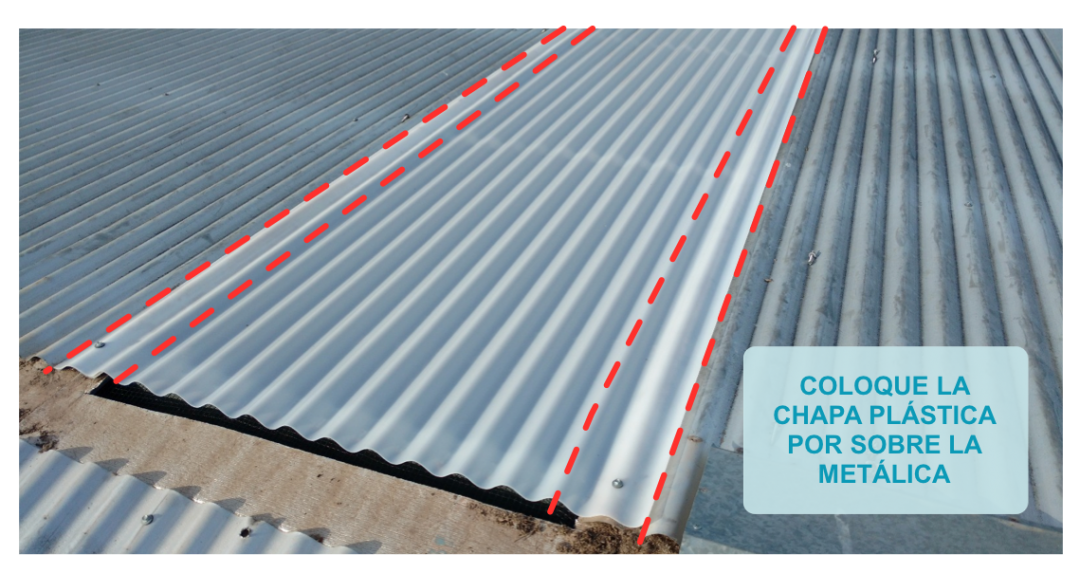

1 – On the side overlap with the metal foil, place our veneer on the metal foil on both sides, as indicated by the red lines in the photo.

This should be done if you are in an area with high temperature and / or have a separation of more than 1 meter between the support points (we recommend that the support points are at 80 cm, 1 meter maximum).

This will help give more structure to our sheet (which is very flexible) because it will rest on the metal sheet.

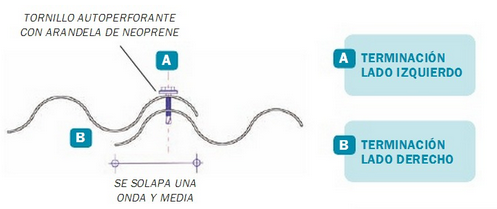

2- Pre-drill the sheet with a drill.

3- Place the self-drilling screw on top of the wave (crest) and respect the height of the wave when tightening the screw (do not overtighten the screw).

4 – The screws that pierce the sheet must have a rubber or neoprene washer to guarantee the seal (we recommend self-drilling screws).

5- To make the sheet firm, it is better to place small plastic or wooden blocks under the self-drilling screw on the crest of the wave (above).

6- The slope must be at least 12% (12 cm high for each meter of sheet length), this avoids the accumulation of water and possible filtration.

7- Our blade can be cut very easily with a cutter, a grinder (with a wooden cutting disc so that it does not melt the plastic) or a jigsaw.

RECOMMENDATIONS FOR INSTALLATION SMOOTH SHEETS

1- The flat sheet is extremely flexible, allowing it to take domed shapes and curves in general, but this same elasticity makes it necessary to place the wooden slats no more than 30 cm from each other, so as not to allow the sheet ” belly”.

INSTALLATION RECOMMENDATIONS

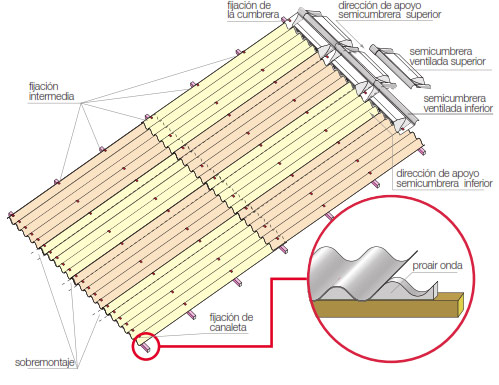

FIXING SCHEME

Arrange the sheets at the eave line in each wave. In windy areas, the sheets can be fixed on intermediate supports in each second wave, taking care to always fix the waves overlapping laterally. If the cantilever length matches the assembly of more sheets, make sure the horizontal overlap corresponds to the support straps.

It is recommended that the overhang of the eave support does not exceed 300 mm.

WARRANTY

Our translucent polypropylene sheets have a manufacturing guarantee, that is, against a failure in the sheet manufacturing process.

They have no guarantee against external weather agents such as hail, storms, etc.